Fashion Terms Cloth to Cover Zippers

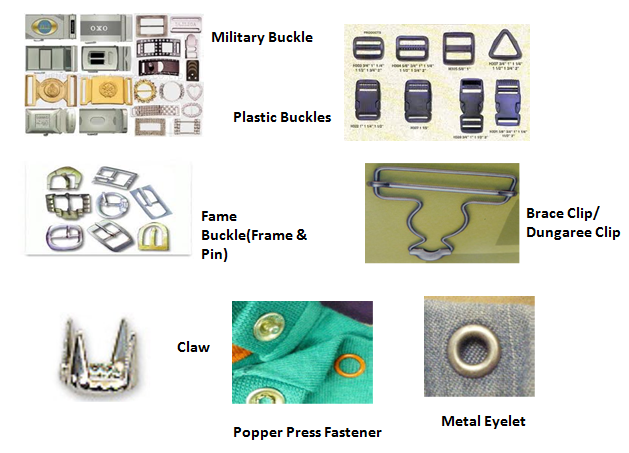

Trims are materials used to decoration or enhance garments. They are visible parts of garments that may be used to increment hanger appeal, provide production differentiation, relate to current way trends, and carry a theme through an entire collection. Trims include a broad range of materials and treatment that may be superficially applied or structurally incorporated into near any blazon of garment. Possibilities for trims are limited only by availability, design inventiveness, costs, and equipment to produce and utilise them.

Trims are grouped into 4 categories: bindings, endings. Apartment awarding and other trims. Selected type of trims, including embroidery thread, laces, appliques, knit trims, labels, sewing thread, attachment etc.

- Type and source of trims:

Trims separate into two categories:

- Decorative trims: information technology is used or practical to enhance the aesthetic entreatment of the garment non much related to garment function and performance. Case: embroidery, appliques, screen printing etc.

- Functional trims: it is integral part of garment they serve of import pat in operation and aesthetic of a garment examples are push, knitted collars and cuffs.

Attachment

Zippers are mechanical slide fasteners. A attachment closer a placket when two rows of interlining elements (teeth, scoops, or coil) are drawn together by a slider. Zippers allow garment to expand for dressing and to become smoothen and fitted when closed. They may provide closer, smoother garment fit and accept more seam stress than buttons, snaps, or other closures. When used equally closures, they are essential to the performance of garments since zipper failures often render garments unusable. Many zipper are also used for their aesthetic value such as those with elaborate or ornate pulls, decorative zipper tapes, or color-coordinated chains.

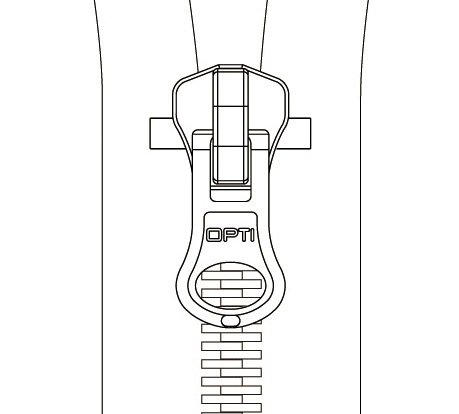

Effigy: nylon zipper, metal attachment and plastic zipper.

- Characteristics of zippers:

Hundreds of unlike sizes and types of zippers are available. For example, YKK i of the world's largest zipper manufacturers, produces approximately two,000 zipper styles in over 400 basic and 1,000 specialty colours in its Macon, Georgia, etc.

Zipper selection may exist based on input from merchandising, pattern, production, and quality assurance with assistance from the zipper manufacturer. Factors that contribute to the aesthetics and performance of zipper include blazon, size, and fabrication of parts, selection and application.

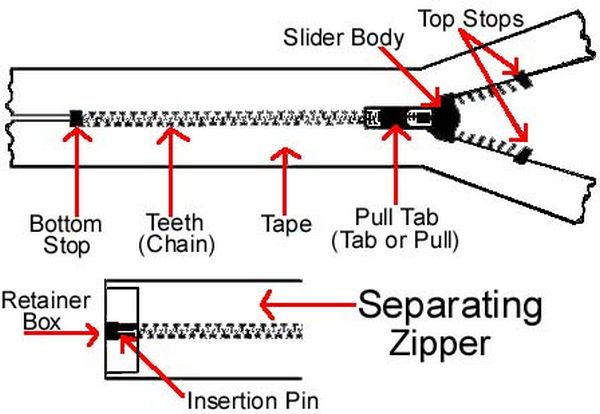

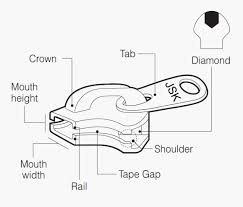

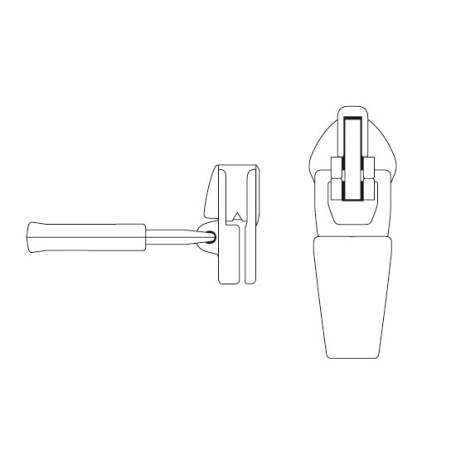

- Zipper parts and materials:

Zipper consist of 4 main parts: two stringers which consist of tape and one-half the chain, one slider, and stop. Definition on the basis of ASTM D 2050-87, the zipper chain consists of two interlocking stringers of teeth, scoops, or coils that lock or unlock with the motility of the slider. Metal chain may exist stronger than continuous coils and are oftentimes used in slacks and jeans where immovability and forcefulness are required. Metal teeth, made of brass, nickel, steel, or zinc are clamped onto zipper tapes. During attachment application, metallic teeth may be removed without damaging the record. This provides a space for stitching or bar tacking beyond the zipper. Teeth tin also be pulled off the tape due to stress during utilise, meaning the zipper would accept to be replaced or the garment discarded. Chains that exercise not rust or corrode are essential for garments that are moisture processed, chemically treated, or garment dyed. Slider will not operate on corroded zipper.

Figure: parts of attachment.

Attachment terminology based on ASTM D 2050-87.

| ZIPPER PARTS | DEFINITION |

Chain:

| A device designed for interlocking, capable of being affixed along the edge of the opposing edges of two tapes and being engaged and disengaged with the aid of slider. |

| A zipper consist of two continuously formed element; coils. |

| A attachment consist of two series of separately formed element; teeth or scoops. |

| A tape, bead, and element assembly that institute i side of the chain. |

| Formed by interlocking several elements of ii stringers. |

| The bearing surface of an interlocking elements by which the chain is independent inside the flanges of the slider. |

TAPES:

| A narrow strip of material to which the fabric is attached. |

| An enlarger section on the inner edge of each tape to which interlockable chemical element are fixed on a separate element attachment. |

SLIDERS:

| A function that opens and close the zipper. |

| The opening in a slider that receives the chain. |

| A part connected to the zipper slider used to operate the slider. |

| The edge of the slider formed to contain the chain. |

| A slider that provide involuntary, positive locking activity on the chain when the pull is released. |

| A slider that incorporates a projection on the pull that fits betwixt adjacent interlocking elements of the attachment. |

| A slider that incorporate curl project on the pull that extended through a window on the slider to effect a locking action by pressing against the concatenation. |

Meridian AND Lesser Assembly:

| A device at the top and lesser of the zipper to forbid the sider from leaving the chain. |

| A part affixed immediately above the chain, holding the tops of the ii stringer together. |

| A zipper having to stringer that are permanently fastened to each other at 1 or both ends. |

| A attachment fitted with special components at the lesser of a chain and so as to permit complete disengagement and and so reengagement of the ii stringers. |

Table (one)

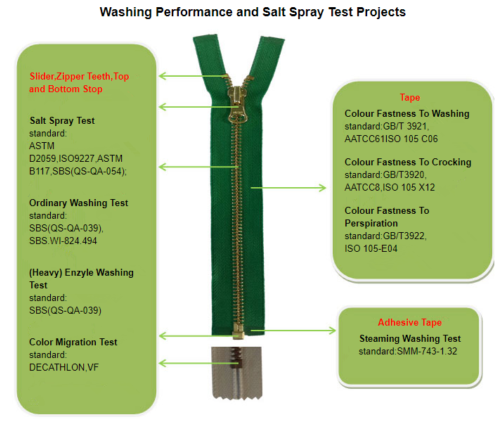

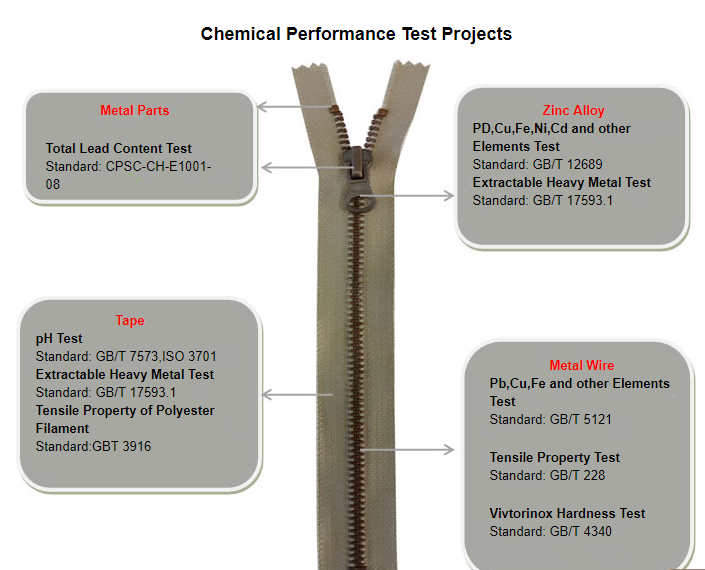

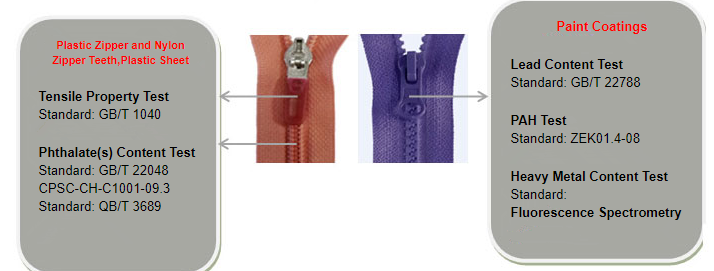

- Testing method of zipper:

United states –ASTM (American society for testing and material).

| Testing Standard | Particular |

| terminology related to zippers |

| test method for measuring the durability of zippers to laundering |

| exam method for measuring the colourfastness of zippers to dry-cleaning |

| test method for measuring the colourfastness of zippers to light |

| test method for measuring the colourfastness of attachment tapes to crocking |

| exam method for measuring the colourfastness of zippers to laundering |

| examination method for measuring the immovability of zippers to dry-cleaning |

| examination method for measuring the resistance of zippers to salt spray (fog) |

| test method for measuring the dimension of zippers |

| exam method for measuring the forcefulness of zippers |

| test method for measuring the operability of zippers |

Table (2)

Precaution on zipper use:

- Rough Slider Operation

Do not force the slider fifty-fifty if it doesn't move smoothly, or it may cause the elements to engage incorrectly.

Utilize paraffin or wax on both the front end and back surfaces of the elements, then move the slider back and along to regain smooth performance.

- Crude Slider Operation

Do not force the slider even if it doesn't move smoothly, or it may cause the elements to engage incorrectly.

Apply paraffin or wax on both the front and back surfaces of the elements, and then motion the slider back and forth to regain polish performance.

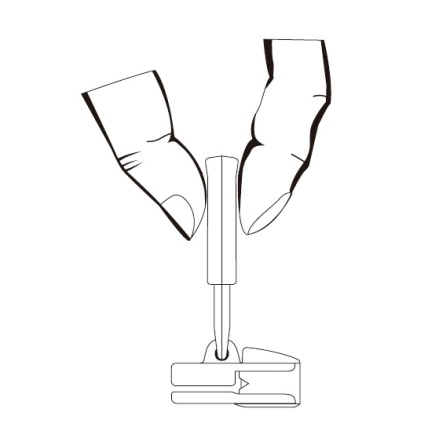

- Fabric Caught in Slider

A slider may take hold of the fabric, hampering its operation.

Avert forcing it to move or information technology volition worsen the problem.

Slowly move the slider while pulling out the caught fabric.

Delight allow enough room for the slider to move smoothly when sewing the zipper onto the fabric

- Proper Laundry Procedure

Brand sure to completely close all the zippers when using the washing/drying machines. Incompletely closed zippers may go entangled with other items and result in chemical element or slider damage or damage to the other particular'southward fabric.

Long or slim slider pull-tabs may become caught in the drum holes, causing breakage, and then the use of a laundry net for these items is recommended.

Later on the drying process, practice not operate the zipper until the garment temperature has cooled downwardly to normal.

Strong alkaline detergent or chlorinated bleach may affect zipper operation. In such cases, employ softeners, alkane series or wax to regain the smoothness.

Do not pre-soak garments with zippers in a washing solution, or it may cause pregnant damage.

- Awarding of zippers:

- Denim jeans.

- Shirt.

- Jacket.

- Numberless.

- Shoes.

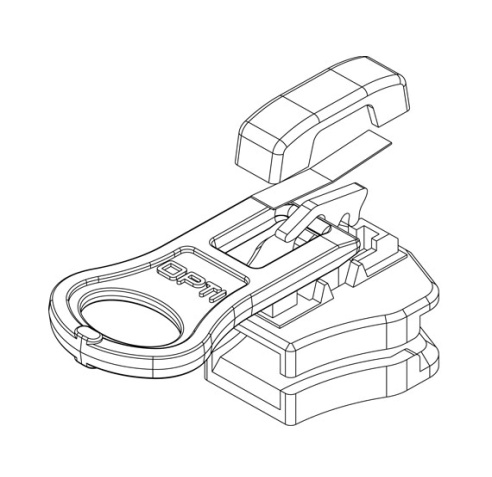

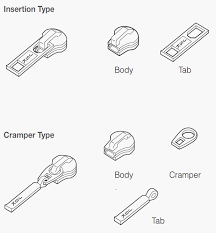

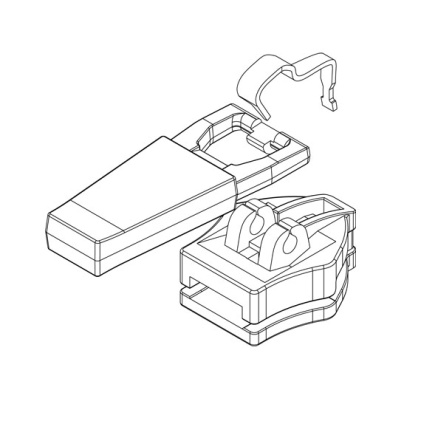

- Zipper lock and Slider

The slider is a component that joins/separates a attachment when information technology is moved up/downwardly along the chain.

Zipper sliders tin be classified into various types, based on the types of zippers, namely, nylon sliders, metal sliders and plastic sliders, which differ from each other. Sliders installed on nylon zippers feature asymmetrical top and bottom sides, with the top side more flat than the lesser side, while sliders used for metallic and plastic zippers share symmetrical pinnacle and bottom sides.

Apart from the nomenclature based on the types of zippers, sliders can too be differentiated according to the functioning of the locking arrangement. They work the all-time on the items advisable for their functioning.

Locking is where the slider remains stagnant, without moving up and down the concatenation unexpectedly. Generally, attachment sliders can be seen in the following categories based on the locking machinery:

- Car-lock sliders

- Semi-auto lock sliders

- Non-lock sliders

Automobile lock sliders: Are those that will not move unless at that place is an external force on their pull tabs.

Non lock sliders: Are those that will unfasten even if slight forcefulness is applied on any slider office or even when the teeth are beingness pulled autonomously.

Semi auto lock sliders: Follow a elementary mechanism wherein the locking and unlocking of the sliders depend on the movement of the pull tabs.

Awarding of dissimilar types of zipper sliders based on the locking mechanism.

Automobile-lock sliders: garments, sportswear, outerwear, jackets, skirts, dresses, etc.

Non-lock sliders: numberless, handbags, baggage, tents, bed covers, etc.

Semi-auto lock sliders: jeans and pants

Auto-lock slider: Within this slider at that place is a locking mechanism activated by a leaf jump.

Locked at the meridian: This locking mechanism secures the slider position at the top of the zip immediately as the puller is released.

Opening/closing: Similarly, as soon every bit the puller is tensioned /pulled the lock is disengaged and the slider tin can be moved freely

Non-lock sliders: numberless, handbags, baggage, tents, bed covers, etc.

Non lock sliders are those that volition unfasten even if slight force is practical on whatsoever slider part or even when the teeth are being pulled apart.

Non Lock Slider: The pull-tab does not lock at any position on the body. No locking machinery.

.Flat-lock Slider/semi automobile lock slider: Semi Car-lock / Flat-lock slider – This slider is fitted with a locking mechanism that is lifted /operated using a cam action.

.Flat-lock Slider/semi automobile lock slider: Semi Car-lock / Flat-lock slider – This slider is fitted with a locking mechanism that is lifted /operated using a cam action.

Locked at the meridian To disengage the locking mechanism and move the slider it is necessary to lift the puller to 90 degrees to fully withdraw the locking pin.

Opening/Endmost: To lock the slider in position the puller should rest flat on the body of the slider, the locking pin volition and so appoint in the teeth holding the slider in identify.

The application scenario of widely used attachment sizes and types are given in the beneath table:

| Size # | Item | Slider and Locking Recommendation | Cloth Type | Application |

| 3 | a | automobile-lock & semi-machine lock | calorie-free | pocket zero, front fly, sleeves open |

| three | Nylon | car-lock & non-lock | ultralight,light | pocket cypher, coating cover, cushions, front end fly, half placket, front zipper, sleeves open up |

| 3 | Nylon | invisible (mesh blazon) | ultra lite | skirt, wearing apparel, pocket zip |

| 3 | Nylon | invisible (woven type) | light | trousers, skirt, dress, cushions, half placket |

| three | Plastic | car-lock | light | pocket nil, sleeves open, front cipher |

| 3 | 50 Type | pin-lock | light to medium | trousers, skirt, forepart fly |

| 4 | Metal | semi-automobile lock | medium | front fly in jeans |

| four | Nylon | machine-lock & not-lock | medium | pocket zip and front end fly |

| 5 | Metal | semi-auto lock & machine lock | Medium and medium heavy | front wing |

| 5 | Metal | automobile-lock | medium and medium heavy | front end aught and pocket zip |

| 5 | Nylon | auto-lock & semi-auto lock | medium and medium heavy | front zip, pocket zip, leg bottom, sleeves, detachable legs, detachable inner jacket |

| v | Plastic | auto-lock | medium and medium heavy | front nix, detachable inner jacket, pocket nothing |

| viii | Coil | machine-lock | medium heavy and heavy | camping tent & sleeping bag |

Table (3)

An Article Past:-

Vishwadeepak

National Institute of Way Engineering,

Bengaluru

- Apparel manufacturing sewing and analysis of product: Glock.

- https://www.zippersource.com/materials/

- Image Link

- https://world wide web.sbs-zipper.com/web log/meridian-5-testing-standards-in-the-global-zipper-industry/

- https://world wide web.sbs-zipper.com/weblog/acme-5-testing-standards-in-the-global-zipper-industry/

- https://www.sbs-zipper.com/quality_control.html ↑

- YKK

- http://world wide web.fibre2fashion.com/industry-article/7926/lock-vs-non-lock-attachment-sliders

- http://www.globalsources.com/si/AS/BZS-Zipper/6008839521500/pdtl/Zipper-Slider/1039653563.html

- Textile Value Chain

- http://www.coatsindustrial.com/en/information-hub/footwear-expertise/zip-tips-for-footwear#intendance

0 Response to "Fashion Terms Cloth to Cover Zippers"

Post a Comment